This machine can press various powder materials into spheres of different shapes and sizes according to different molds. The shapes can be customized and the forming rate is as high as 99%.

Email:

asterma@believe-machine.comMailbox:

asterma@believe-machine.comTelephone:

tel:+86 18638773317

Roller Pellet Machine can press charcoal powder, coal powder, dry powder, coke powder, carbon powder, iron scale, mineral waste residue, iron powder, various powder material and into different shape and size balls according to the different moulds. The shapes can be in different forms of oval, egg, pillow, etc. This machine is widely used in charcoal, coal industry and metallurgy industry.

The main part of the roller pellet machine is a pair of rotating shafts of the same size, with many hemispherical sockets of the same size and regularly arranged on the surface.

The processed material will enter through the feed port and be squeezed into the hemispherical sockets on both sides under the action of its own gravity and the pressure of the rollers on both sides. The hemispherical sockets on both sides merge into a complete sphere, the raw materials inside will gradually be compressed, and finally form the coal ball briquette. With the further movement of the shaft, the formed coal ball falls from the discharge port.

1. Coal/coke/charcoal powder.

2. Metal powder: Iron powder, magnesium oxide powder, copper powder, chromium ore, lead, zinc scrap, bauxite, nonferrous metal powder, silicon manganese alloy powder etc.

3.Mineral powder: aluminum powder, toner, gypsum, sludge, desulphurization gypsum powder etc.

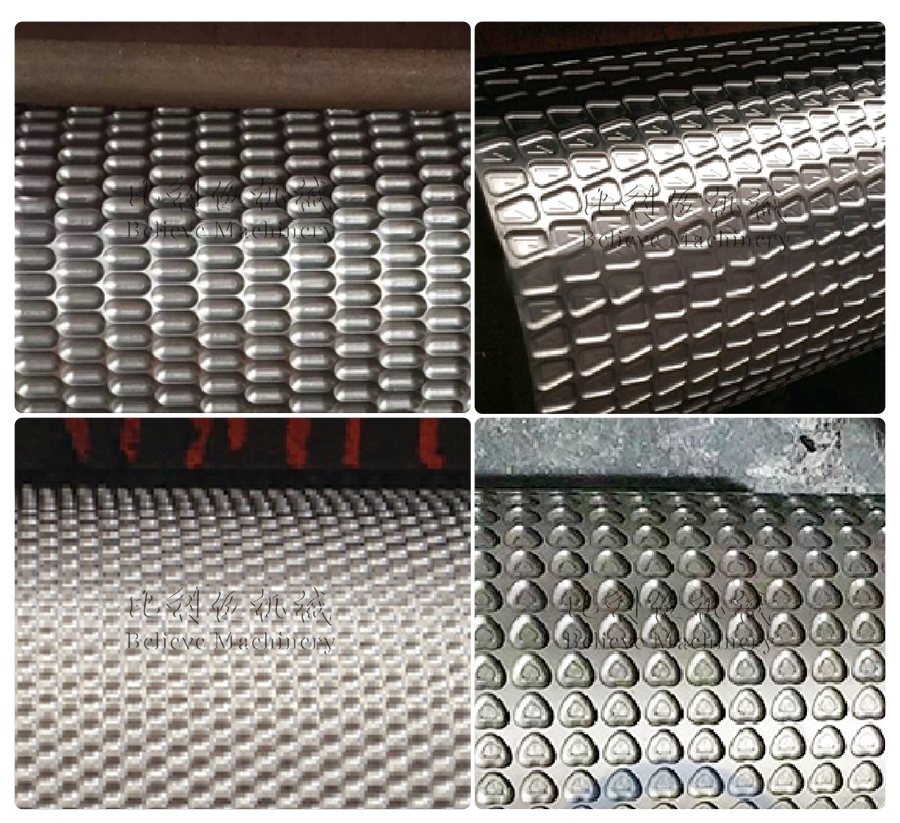

By changing molds, you can get diffferent shape briquettes:

Final Products

↓ ↓ ↓

We have a professional transportation team and reasonable transportation methods. During transportation, we will surround the machine with thickened export wooden boxes to protect the machine from impact and friction. So you don’t have to worry about the machine being damaged during transportation.

Email: asterma@believe-machine.com

Telephone: +86 18638773317

Office address: No. 185, 14th Floor, No. 55 Mudan Road, High Tech Zone Zhengzhou City, Henan Province,China

Factory address: Dahuangye Industrial Zone, Gongyi City, Henan Province