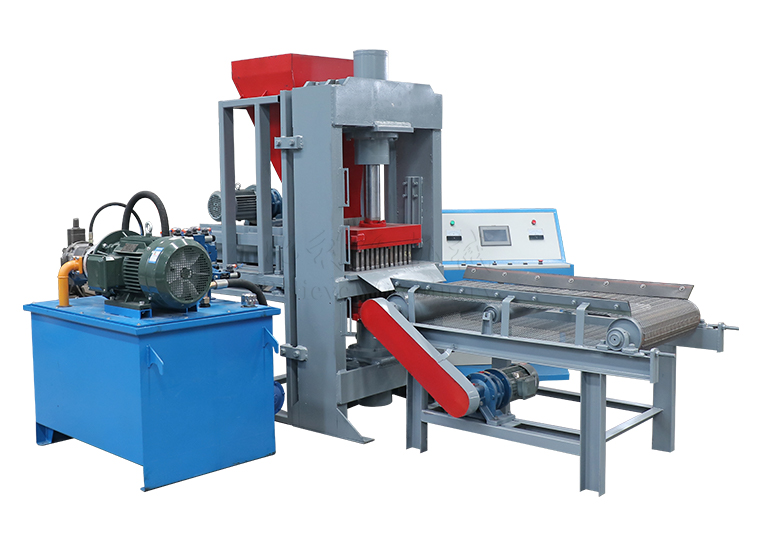

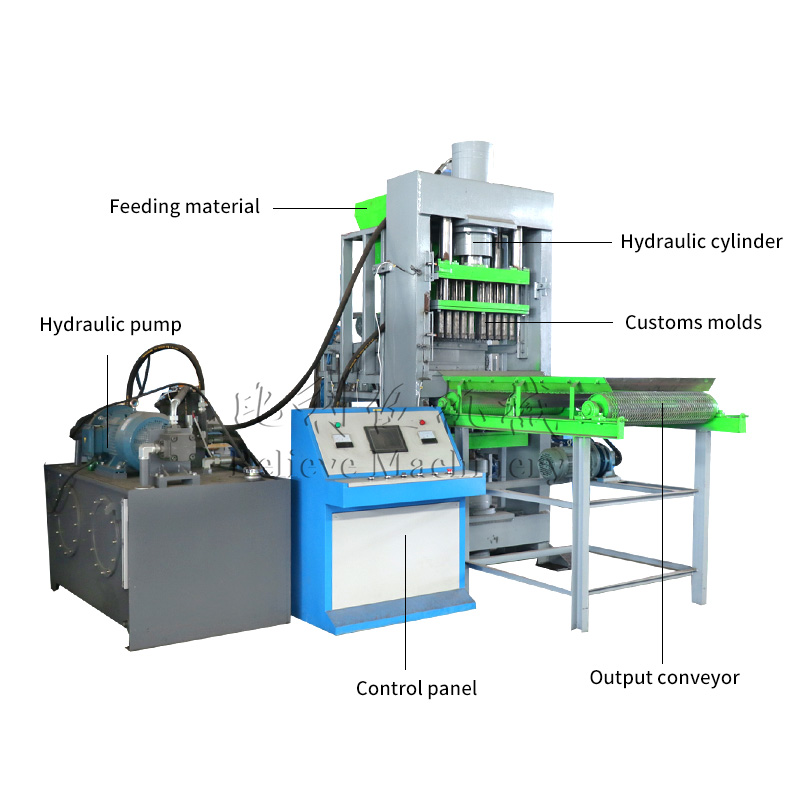

Hookah Cube Round Square Shape Charcoal Press Machine is composed of hydraulic system, PLC system, Host mold, Big feeding port, Mesh belt conveyor. 1). 80-120tons pressure. 2). raw materials can be: Coconut shell charcoal, charcoal powder, coal powder, sawdust charcoal, etc. 3). briquette height can be adjusted. 4). whole machine includes: main machine, PLC, hydraulic system, mesh belt conveyor.

Email:

asterma@believe-machine.comMailbox:

asterma@believe-machine.comTelephone:

tel:+86 18638773317

The Hydraulic charcoal press machine is a kind of charcoal powder molding equipment, which uses high pressure to press the charcoal powder into charcoal briquettes of different shapes. The machine is widely used in charcoal powder and coal powder forming and is essential equipment in the process of charcoal powder processing. After being pressed by the briquetting machine, the charcoal briquette has the advantages of being hard and non-divergent, high density, easy to ignite, long burning time, uniform heating, etc.

Hydraulic cylinder:The pressure is adjustable. The hydraulic cylinder is on top of the machine. And the rest of the lines are in the lower part of the machine. Therefore, the whole machine is very space-saving.

Molds:Can choose the shape what you need.

PLC control panel:It is an all-in-one one-button start for the device, easy to operate.

It can press all kinds of charcoal powder into Shisha Hookah charcoal briquettes and BBQ charcoal briquettes with high pressure.

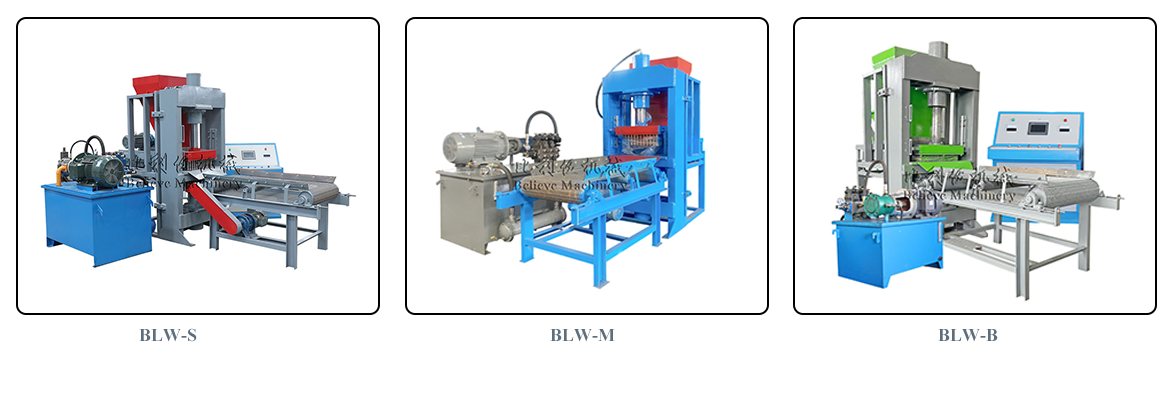

| Model | BLW-S | BLW-B | BLW-B |

| Capacity | 200-400kg/h | 600-800kg/h | 800-1000kg/h |

| Motor | 15+2.2+1.5kw | 15+2.2+1.5kw | 15+2.2+1.5kw |

| Raw material |

charcoal powder, coal powder or other model charcoal powder |

||

Hydraulic charcoal press machine working in customer factory:

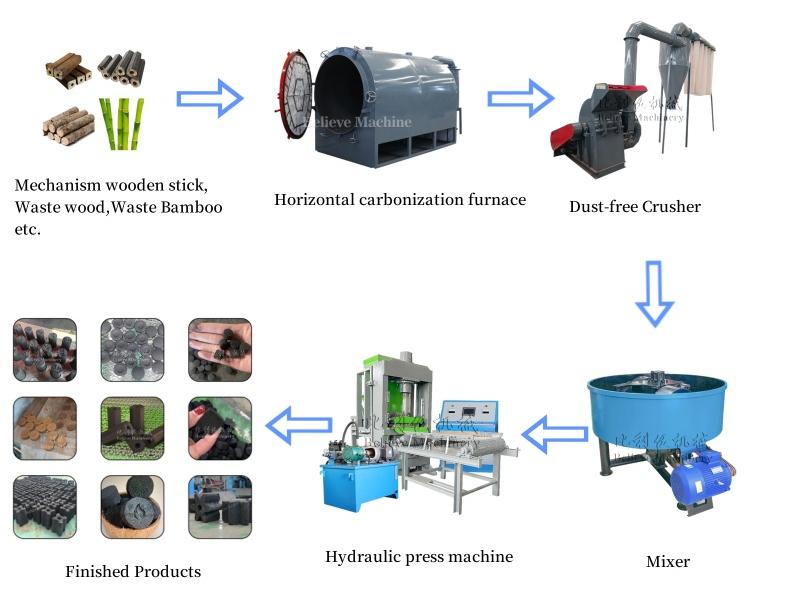

1-Horizontal Carbonization Furnace: Carbonize raw materials into charcoal

2-Crusher: Crush the charcoal into charcoal powder

3-Mixer: Mix charcoal powder with some binder

4-Hydraulic Press Machine: Shape the charcoal powder and get the final products.

We have a professional transportation team and reasonable transportation methods to ensure that the goods are delivered to the destination on time. During transportation, we will surround the machine with thickened export wooden boxes to protect the machine from impact and friction. So you don’t have to worry about the machine damage during transportation.

We look forward to working with you to create a bright future for the charcoal industry.

Email: asterma@believe-machine.com

Telephone: +86 18638773317

Office address: No. 185, 14th Floor, No. 55 Mudan Road, High Tech Zone Zhengzhou City, Henan Province,China

Factory address: Dahuangye Industrial Zone, Gongyi City, Henan Province