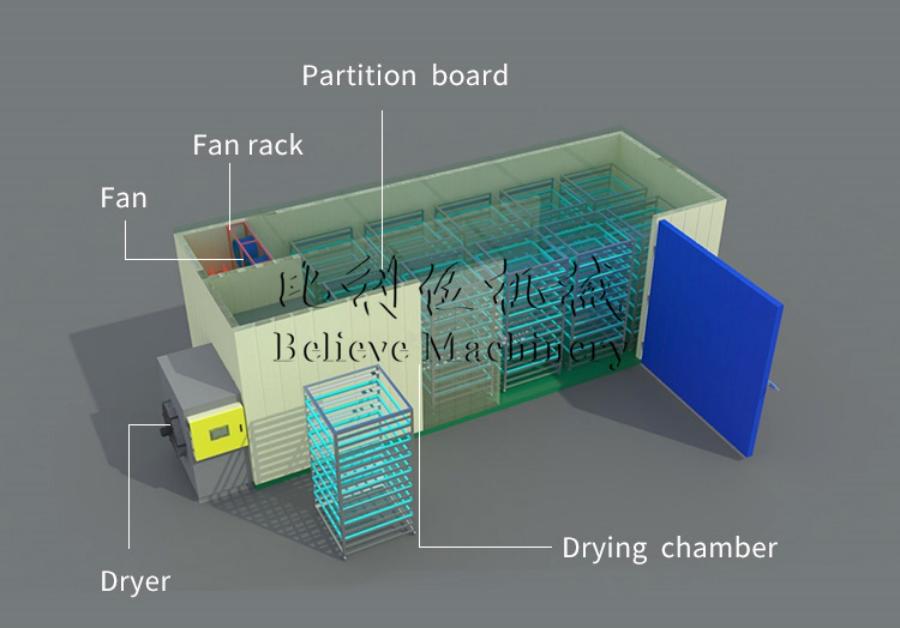

Heat Pump Dryer/Drying Machine takes advantage of the reversed Carnot principle, absorbing the heat from around and sending the heat to the materials which will be dried. This kind of dryer is mainly composed of heat pump dryer and drying chamber. This dryer will be controlled by touch screen controller, and the temperature can be adjusted. It has low electric consumption.

Email:

asterma@believe-machine.comMailbox:

asterma@believe-machine.comTelephone:

tel:+86 18638773317

The heat pump dryer uses the air around the environment to transfer heat to the surface of the material to wet the surface. With the latest cold, warm air drying system, drying temperature of this dryer ranges from 10℃ to 85 ℃. It is more more effectively than any traditional drying equipment in protecting the drying material color, smell, taste, individual form and nutrition.

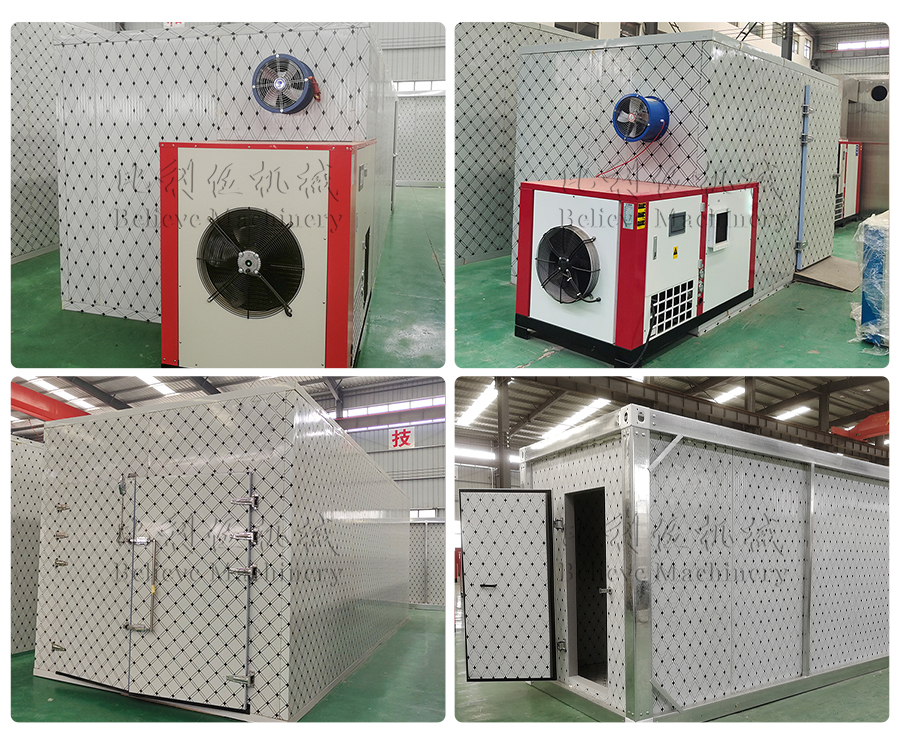

The heat pump dryer integrates all components through an integrated design. The actual installation is very simple. You only need to connect the ventilation pipe, and the stable heat pump can work around the clock. The equipment is not restricted by weather or site, which expands the scope of application and improves drying efficiency.

Heat Pump Dryer takes advantage of the reversed Carnot principle, absorbing the heat from around and sending the heat to the materials.

This kind of dryer is mainly composed of heat pump dryer and drying chamber.

This dryer will be controlled by touch screen controller, and the temperature can be adjusted. It has low electric consumption.

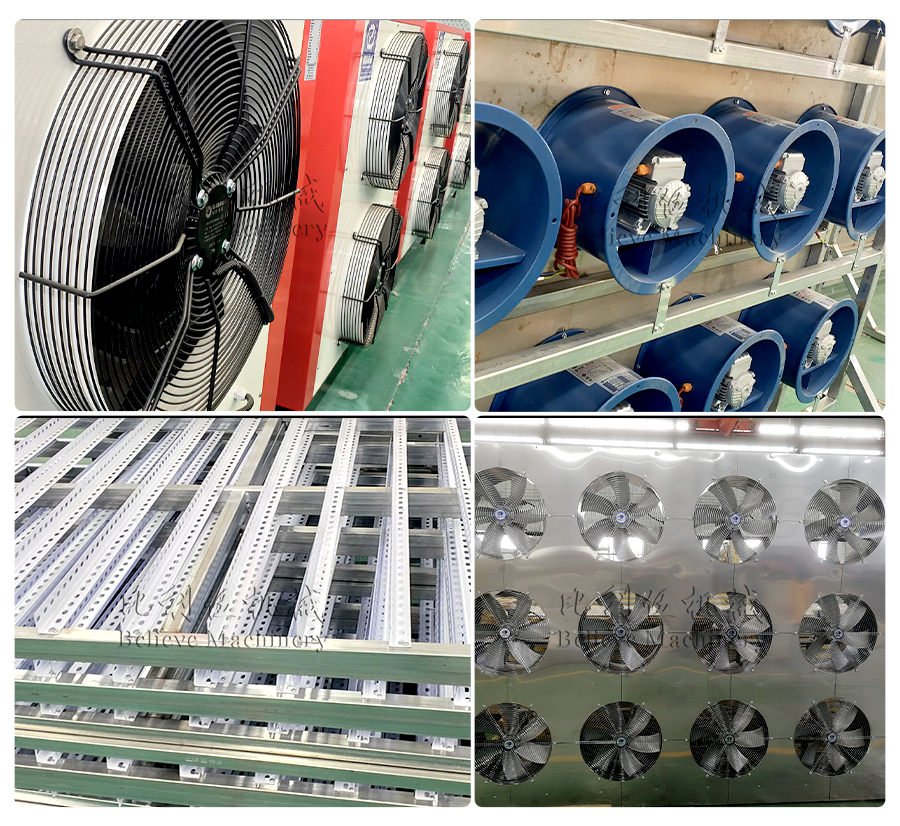

◊ Pieces for dryer

Dryer box will separate different pieces, its easy loading in the container, save space and shipping cost.its very easy installation by screw.

◊ Trolley and trays

Put shisha charcoal or BBQ charcoal in the trays,then put trays in the trolley, and push trolley inside dryer room to drying

◊ Heat pump for the dryer

Heat pump working like air conditioner,save energy, The working principle is: the refrigerant is compressed by the compressor to become high-temperature and high-pressure gas, enters the condenser, and condenses liquefied heat, which is used to heat the drying room to provide the temperature of the drying room. Hot air vaporizes and evaporates the moisture in the material. The dehumidification system will discharge the evaporated water vapor to achieve the purpose of dehumidifying the dry material. The dehumidification system uses a heat recovery device. The recovered heat can use to heat the fresh air, which can save 60% -70% of the fresh air preheats energy consumption to achieve further energy savings.

Vegetables like Radish, lettuce, pumpkin, carrots, spinach, cassava,etc

Fruits like Apple, lemon, mango slices, dried longan, dried longan,etc

Meat: Sausage, beef, duck, ham,etc

Others it can dry noodle/ wooden /stick incense/herbs /floers ect.

In the charcoal industry, we can use it to dry BBQ charcoal and shisha charcoal for quick packaging.

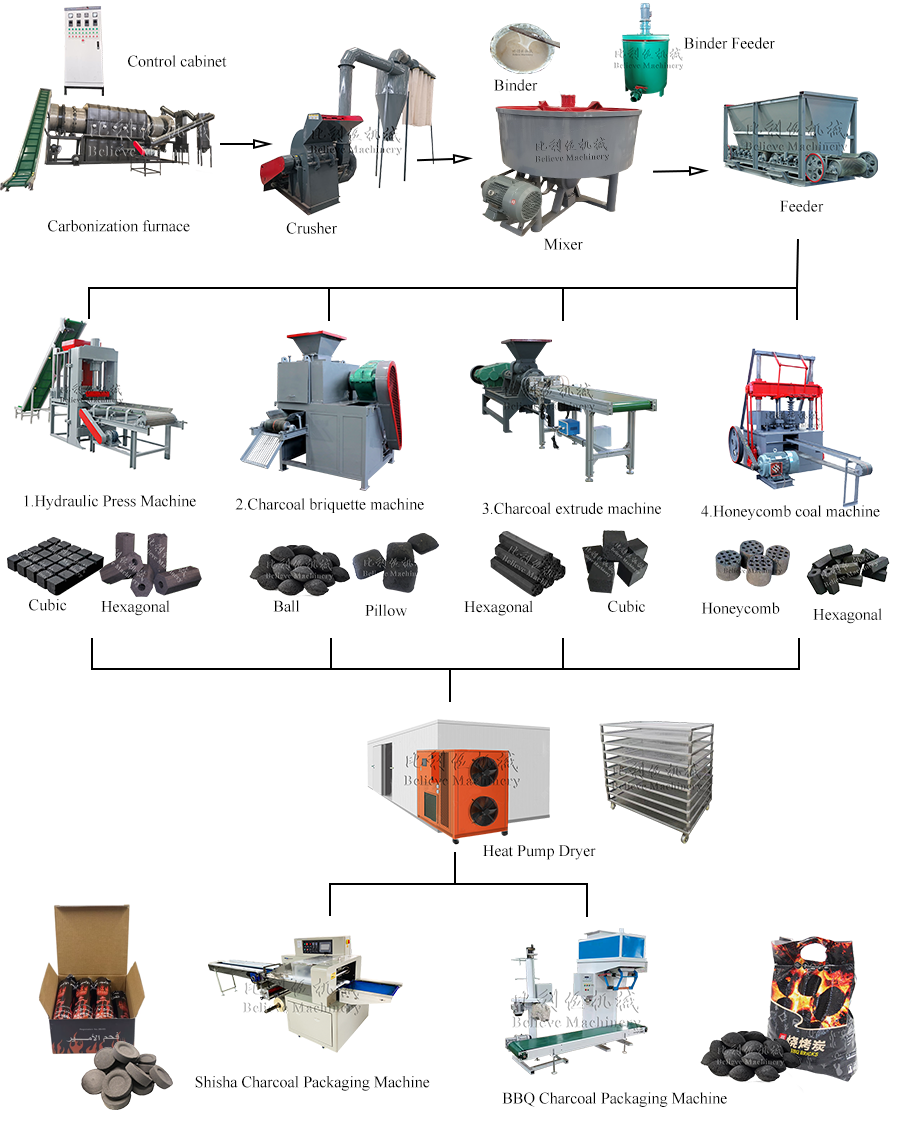

1-Carbonized: Making biomass become biochar;

2-Crushed: Making charcoal become charcoal powder;

3-Mixed:Mixing charcoal powder with some binder;

4-Shaped:Choose the corresponding machine for molding;

5-Dryer: Drying the charcoal briquette by heat pump dryer for quick packaging;

6-Packaging:Packaging finished charcoal products.

CONTACT US NOW!

We look forward to working with you to create a bright future for the carbonization industry.

Email: asterma@believe-machine.com

Telephone: +86 18638773317

Office address: No. 185, 14th Floor, No. 55 Mudan Road, High Tech Zone Zhengzhou City, Henan Province,China

Factory address: Dahuangye Industrial Zone, Gongyi City, Henan Province