This machine can carbonize small sizes of biomass raw materials into biochar, charcoal, and obtain wood tar and wood vinegar. You can get carbon credits through this equipment.

Email:

asterma@believe-machine.comMailbox:

asterma@believe-machine.comTelephone:

tel:+86 18638773317

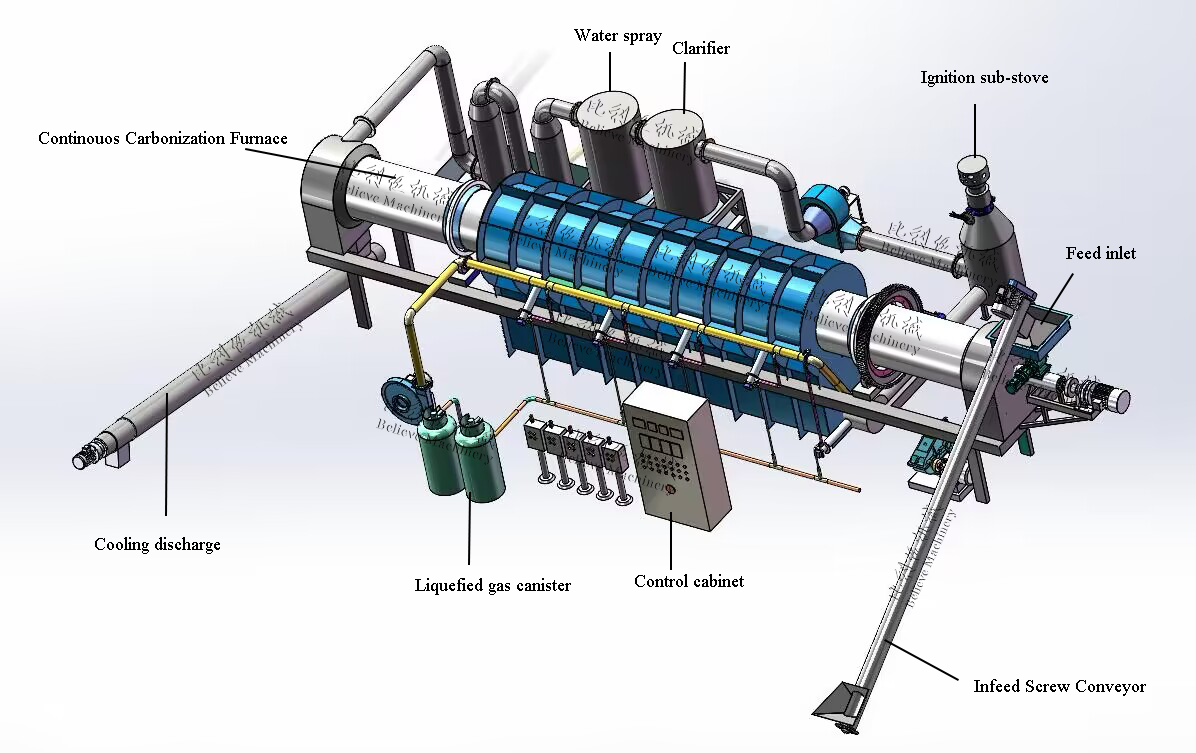

The drum continuous carbonization furnace is an efficient and environmentally friendly carbonization equipment, which is mainly used to pyrolyze biomass raw materials (such as wood chips, straw, fruit shells, coconut shells, etc.) or organic waste under low oxygen and negative pressure conditions to convert them into products such as biochar, combustible gas and tar. Its core feature is the drum design, which can achieve continuous feeding and discharging, and is suitable for industrial large-scale production.

Raw materials: straw, wood chips, bamboo, coconut shells, rice husks and other carbon-containing biomass materials (granular with a diameter of less than 25mm)

Our drum carbonization furnace is equipped with a infeed screw system, horizontal forced feeding, combustion chamber, purification system, screw cooling discharge, etc.

| Model | Capacity(kg/h) | Inner pot size(m) | Furnace size(m) |

| BLWCF-800 | 300-400 | 0.8*10 | 12*1.8*2.5 |

| BLWCF-1000 | 600-800 | 1.0*10 | 12*1.8*2.5 |

| BLWCF-1200 | 800-1000 | 1.2*10 | 12*2.2*2.5 |

| BLWCF-1500 | 1200-1500 | 1.5*10 | 12*2.2*2.5 |

1.Our furnace is equipped with an advanced gas treatment system, which can effectively reduce the emission of harmful gases such as sulfur dioxide, nitrogen oxides and particulate matter. The treated exhaust gas meets or even exceeds international environmental standards, ensuring that your carbonization production process is clean and compliant. By choosing our drum continuous carbonization furnace, you can obtain carbon credits and improve your carbon trading rights.

2.The furnace is designed with an intuitive control panel and automated operating system. The operator can easily set the temperature, feed rate and other key parameters, and the system will monitor and adjust the process in real time. This not only simplifies the operation process, but also reduces the need for highly skilled labor, making it easier for you to manage the production line.

We also provide personalized customization services. Regardless of your production scale or raw material type, we can tailor the most suitable horizontal carbonization furnace solution for you according to your actual needs. Our professional technical team will provide you with technical support and services throughout the process to ensure smooth installation, commissioning and operation of the equipment.

1-Carbonized: Making biomass become biochar

2-Crushed: Making charcoal become charcoal powder

3-Mixed:Mixing charcoal powder with some binder

4-Shaped:Choose the corresponding machine for molding

Note: Add some conveyors can make the whole line automatic.

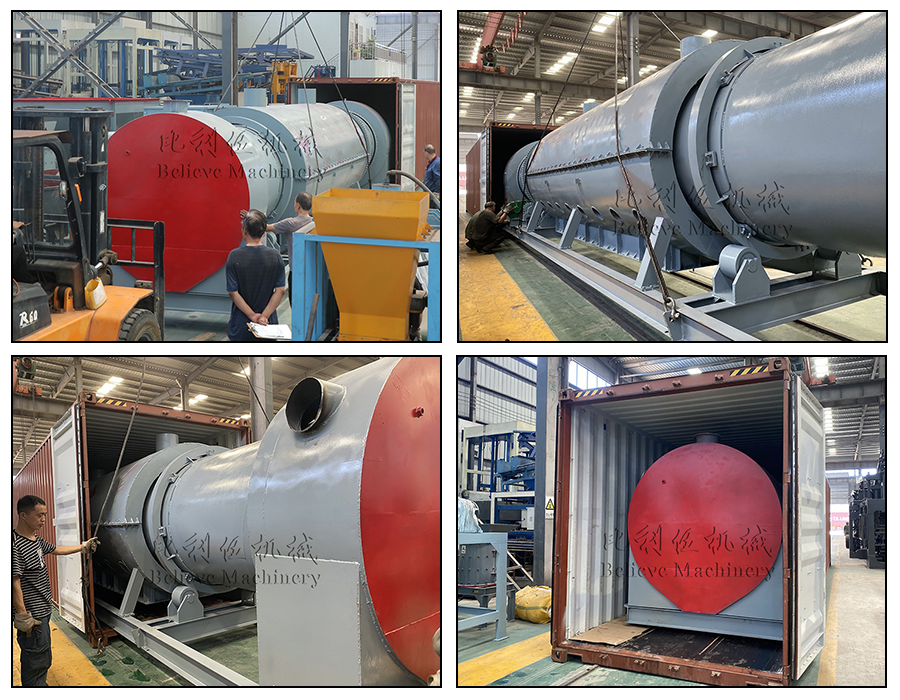

We have a professional transportation team and reasonable transportation methods to ensure that the goods are delivered to the destination on time. During transportation, we will surround the machine with thickened export wooden boxes to protect the machine from impact and friction. So you don’t have to worry about the machine damage during transportation.

If you are currently struggling to find high-quality carbonization equipment, then this continuous carbonization furnace is definitely your best choice! Its excellent performance, efficient energy-saving effect, environmentally friendly production method, and thoughtful customized service will bring unlimited possibilities for your business development.

CONTACT US NOW!

We look forward to working with you to create a bright future for the carbonization industry.

Email: asterma@believe-machine.com

Telephone: +86 18638773317

Office address: No. 185, 14th Floor, No. 55 Mudan Road, High Tech Zone Zhengzhou City, Henan Province,China

Factory address: Dahuangye Industrial Zone, Gongyi City, Henan Province