Charcoal extruder machine, which using the principle of screw extrusion to compress the coal powder into a predetermined shape with a certain intensity. After the coal powder poured into machine chamber,it bears tremendous pressure.With the help of all kinds of shaped molds,it will be shaped into certain shapes.

Email:

asterma@believe-machine.comMailbox:

asterma@believe-machine.comTelephone:

tel:+86 18638773317

The charcoal extrude machine mainly squeezes the raw materials into dense sticks through mechanical pressure:

It needs to crush the raw materials to a certain fineness (such as coal powder needs to be sieved to less than 5mm), and control the moisture (usually 8%-12%), and push the raw materials into the forming mold through the motor-driven spiral shaft, forming a dense stick structure under high pressure, and the formed charcoal stick are cut according to the set length (manually cut or equipped with automatic cutting device), and can be used or sold after natural drying or dryer. The machine both can produce BBQ charcoal(cylinder shape, hexagonal shape, quadrangular shape) and shisha hookah charcoal(cubic shape, round strip shape, hexagonal strip shape).

The charcoal extruder machine adopts the principle of screw extrusion to compress the coal/charcoal powder into shaped briquettes. After the charcoal powder is poured into the feeding hopper, it is propelling forward to the discharging hole of the briquette machine by the screw. From the screw chamber to the mold, space is becoming smaller. Under the tremendous pressure, charcoal passes through the molds and finally form into certain shapes.

The final products of charcoal extrude machine

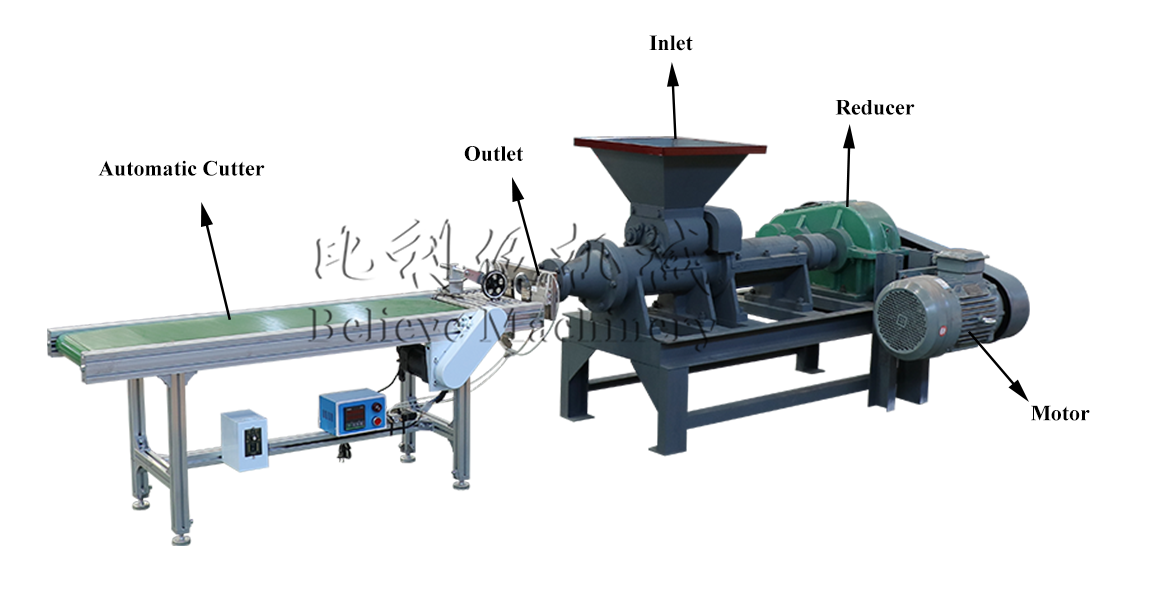

The main structure of the charcoal extrude machine is composed of a motor, a reducer, a screw propeller shaft, a mold, and the final automatic cutter.

We provide customers with a large number of different molds to choose from, and we can also customize them according to customer needs.

The molds and final products of charcoal extrude machine

This machine has a compact design, including the electric motor, reduction box, feeding hopper, screw propelling part, discharging hole, machine base, etc.

1.Pressing charcoal dust into solid or hollow cylinder, square, hexagon shape briquette for barbecue.

2.Different diameter of final briquettes meets with different market requirement.

3.It suitable for different types of carbon powder;no matter forest wastes ot agriculture waste carbon dust.

|

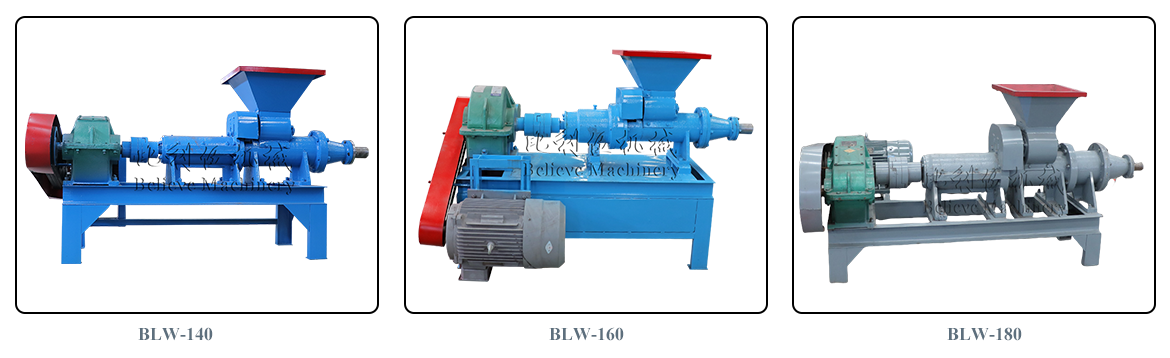

Model

|

BLW140

|

BLW160

|

BLW180

|

|

Capacity

|

1-1.5t/h

|

1.5-2t/h

|

2-3t/h

|

|

Power

|

15kw

|

22kw

|

22kw-30kw

|

| Size | 1.9*1.1*1.17m | 2.2*1.3*1.4m | 2.2*1.3*1.0m |

|

Feeding size

|

≤5mm

|

≤5mm

|

≤5mm

|

Different Model of charcoal extrude machine

We have a professional transportation team and reasonable transportation methods to ensure that the goods are delivered to the destination on time. During transportation, we will surround the machine with thickened export wooden boxes to protect the machine from impact and friction. So you don’t have to worry about the machine being damaged during transportation.

Charcoal extrude machine deliver

CONTACT US NOW!

Email: asterma@believe-machine.com

Telephone: +86 18638773317

Office address: No. 185, 14th Floor, No. 55 Mudan Road, High Tech Zone Zhengzhou City, Henan Province,China

Factory address: Dahuangye Industrial Zone, Gongyi City, Henan Province