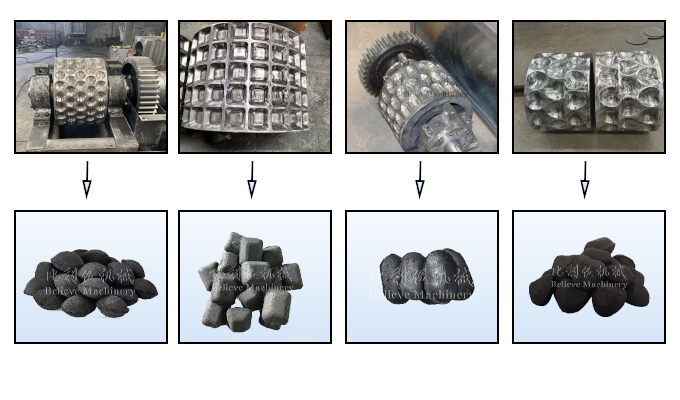

Briquette press machine price can be used to suppress various powders, scrap, waste residue such as pulverized coal, iron powder, coking coal, aluminum ash, iron filings, iron oxide scale, carbon dust, powdered carbon, slag, gypsum, gangue, sludge, kaolin, active carbon, coke breeze and so on. It can press the coal dust, charcoal powder and carbon black to different shapes,like square,ball,egg,bread,pillow,briquette shapes and so on.There are many different kinds of molds,so we also can make molds according to your needs.

Capacity(t/h): 1-30

Machine Weight(kg): 600-22000

Email:

asterma@believe-machine.comMailbox:

asterma@believe-machine.comTelephone:

tel:+86 18638773317

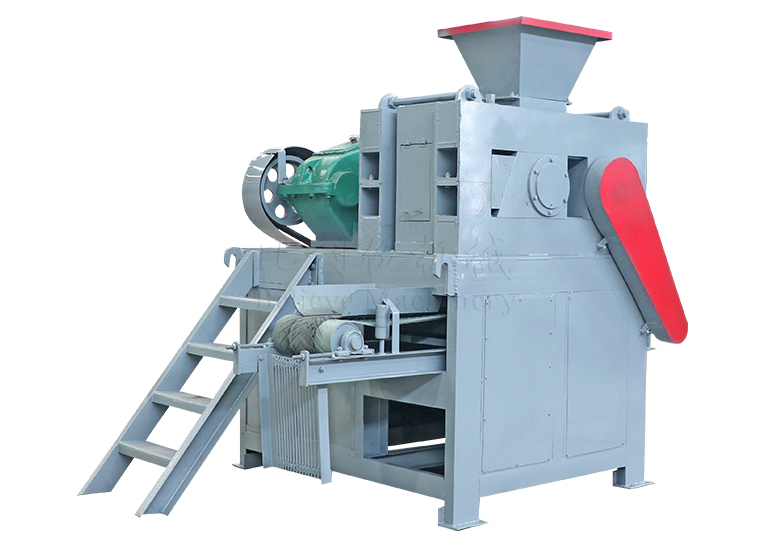

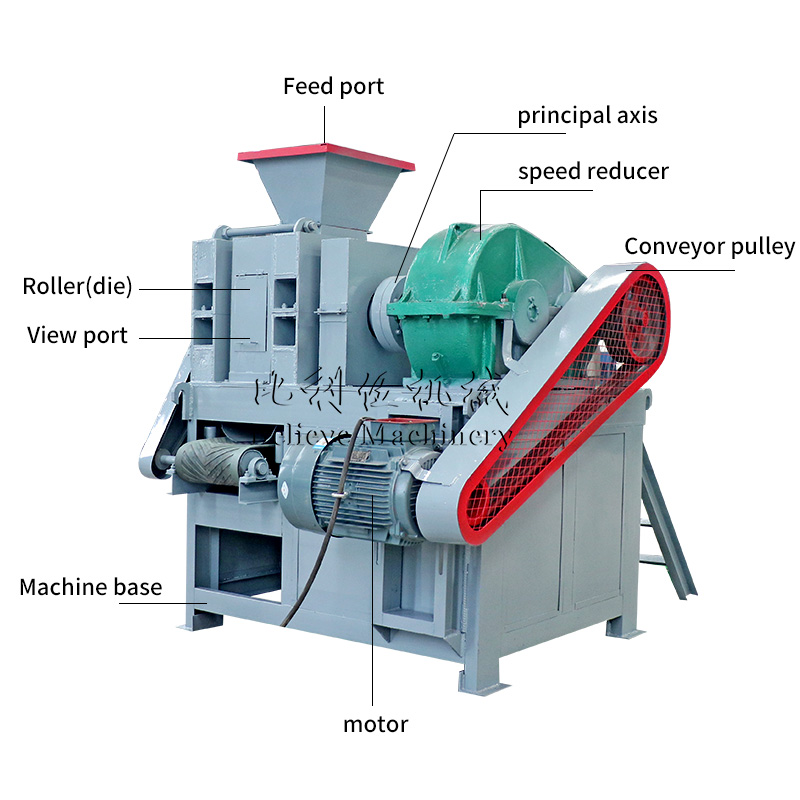

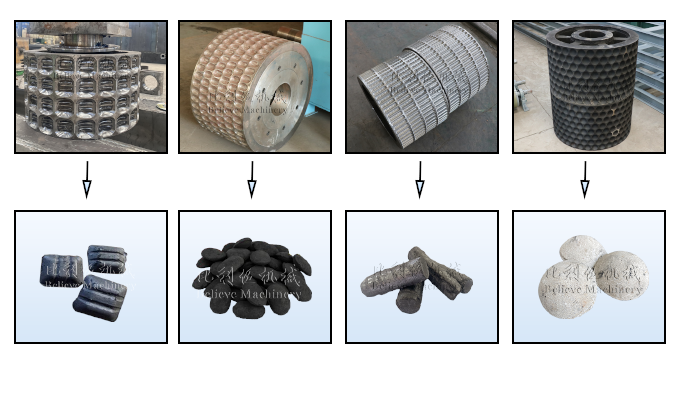

Charcoal Ball Briquette Machine can press charcoal powder, coal powder, dry powder, coke powder, carbon powder, iron scale, mineral waste residue, iron powder, various powder material and into different shape and size balls according to the different moulds. It is mainly used for fuel, boiler heating or for cooking and BBQ. The shapes can be in different forms of oval, egg, pillow, square ,etc. This machine is widely used in charcoal, coal industry and metallurgy industry.

The main part of the charcoal briquette machine is a pair of rotating shafts of the same size, with many hemispherical sockets of the same size and regularly arranged on the surface.

The processed material will enter through the feed port and be squeezed into the hemispherical sockets on both sides under the action of its own gravity and the pressure of the rollers on both sides. The hemispherical sockets on both sides merge into a complete sphere, the raw materials inside will gradually be compressed, and finally form the coal ball briquette. With the further movement of the shaft, the formed coal ball falls from the discharge port.

The charcoal briquette forming machine mainly includes hopper, gear, press roller, conveyor belt, motor, speed controller, and other structures. Two of the gears drive two roller molds. Because the pressure rollers move towards each other, the two hemispheres can form a complete sphere.

1. Coal/coke/charcoal powder.

2. Metal powder: Iron powder, magnesium oxide powder, copper powder, chromium ore, lead, zinc scrap, bauxite, nonferrous metal powder, silicon manganese alloy powder etc.

3.Mineral powder: aluminum powder, toner, gypsum, sludge, desulphurization gypsum powder etc.

By changing molds, you can get diffferent shape briquettes :

| Model | Power (KW) | Capacity (kg/h) |

| BLW-290 | 5.5 | 1000-2000 |

| BLW-360 | 7.5 | 2000-3000 |

| BLW-430 | 22 | 4000-5000 |

| BLW-650 | 45 | 8000-10000 |

1. Carbonization Furnace: Carbonize the raw materials into charcoal.

2. Crusher: Crush the charcoal into charcoal powder

3. Mixer: Mix the charcoal powder with binder

4. Feeder: Store the mixed charcoal powder

5. Charcoal Ball Briquette Machine: Making charcoal powder become charcoal briquette

6. Packaging Machine: Packed the charcoal briquettes.

Note: The whole line can become automatic by add the conveyors.

Email: asterma@believe-machine.com

Telephone: +86 18638773317

Office address: No. 185, 14th Floor, No. 55 Mudan Road, High Tech Zone Zhengzhou City, Henan Province,China

Factory address: Dahuangye Industrial Zone, Gongyi City, Henan Province